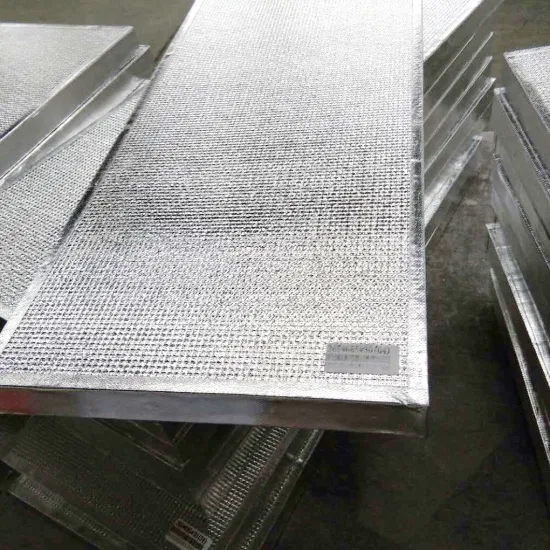

Insulation Material 3240 Epoxy Fiberglass Sheet

1.Product description: Thickness: 0.3mm-80mm Dimension: 1020*2020mm 1020*21220mm 1220*2440mm Color:Yellow(other colors c;

Basic Info.

| Model NO. | 3240 |

| Classification | Hybrid Insulation Materials |

| Certification | ISO9001 |

| Color | Yellow and Green and Orange and Black and Red |

| Brand | No |

| Density | 1.9-2.1g/cm3 |

| Sample | Free for A4 Size |

| Thickness | 0.1-120mm |

| Transport Package | Pallet |

| Specification | 1020*2020mm 1020*1220mm 1220*2440mm |

| Trademark | No |

| Origin | China |

| HS Code | 3921909090 |

| Production Capacity | 6000tons/Year |

Product Description

1.Product description:Thickness: 0.3mm-80mm

Dimension: 1020*2020mm 1020*21220mm 1220*2440mm

Color:Yellow(other colors can be customized)

Customization: Processing based on Drawings

3240 Epoxy phenolic glass fiber laminated sheet:This product is a laminated product made of electrical purposed alkali-free glass cloth impregnated with epoxy phenolic resin by hot pressing.The thermostablity is grade B.It has good mechanical and dielectrical properties,

Applicable to mechanical, electrical, electronic, electrical and other fields. It is also used in the processing of insulating parts, and processed into all kinds of insulating parts and equipment insulating structural parts, which can be used in wet environment conditions and transformer oil.

2.Compliance with standards:

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates - Part 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating materials - electrical thermosetting resin industrial hard laminates - Part 3-2 of the individual material specification EPGC201.

3.Features:

1.Good mechanical properties;

2.Good dielectrical properties;3.Moisture resistance,suitable under

wet environment and transformer oil.

4.Good machinability properties

5.Temperature resistance:Grade B

4.Application:

1) Used in the mechanical performance requirements of a high motor, electrical equipment and insulating structural parts

2) ICT,ITE rule the processing of the insulation parts,test fixtures,silicon rubber keypads mold

3) Fixture plate , mold plywood,countertops grinding plate,packaging machines,comb,etc

5.Technical Date:

| Main Performance Index | |||||

| NO. | ITEM | UNIT | INDEX VALUE | ||

| 1 | Density | g/cm³ | 1.8-2.0 | ||

| 2 | Water absorption Rate | % | ≤0.5 | ||

| 3 | Vertical bending strength | MPa | ≥340 | ||

| 4 | Vertical compression strength | MPa | ≥350 | ||

| 5 | Parallel impact strength (charpy type-gap) | KJ/m² | ≥33 | ||

| 6 | Parallel impact strength (cantilever beam method) | KJ/m² | ≥34 | ||

| 7 | Parallel shear strength | Mpa | ≥30 | ||

| 8 | Tensile strength | MPa | ≥200 | ||

| 9 | Vertical electric strength(in oil of 90ºC±2ºC) | 1mm | KV/mm | ≥14.2 | |

| 2mm | ≥11.8 | ||||

| 3mm | ≥10.2 | ||||

| 10 | Parallel breakdown voltage(in oil of 90ºC±2ºC) | KV | ≥35 | ||

| 11 | Dielectric dissiption factor(50Hz) | - | ≤0.04 | ||

| 12 | Insulation Resistance | Normal | Ohm | ≥5.0×1012 | |

| After soaking for 24hours | ≥5.0×1010 | ||||

Jiujiang Xinxing Insulation Material Co., Ltd. is a joint-stock enterprise of Jiujiang Xinxing Group. The company was established in March 2003, the annual production of all kinds of insulating materials, functional composite materials more than 6000 tons.The main production of various types of electrical insulation materials, electronic insulation and reinforcing materials, reinforced plastic board series, high temperature resistant insulation materials series, high performance flame retardant insulation materials series and special functional composite materials.The products are widely used in PCB mold, fixture, generator, switchgear, rectifier and other fields in electrician, electronics and electric appliance industry.Company to develop high performance, high temperature resistant, high dielectric materials are widely used in 5 g communications, new energy vehicles, rail transportation, large transformer substation, large generating set, nuclear power, wind power generators, and other fields, more developed type functional composite materials are widely used in national defense, aerospace, high-speed rail, nuclear power, disaster relief, and other fields;The company has advanced insulation materials CNC processing equipment, can provide customers with drawing finishing and other professional services.After nearly 20 years of development, Xinxing Insulation has grown into a first-class insulating material production enterprise in China, integrating research and development, production, sales and service.

The company is located in the beautiful Jiujiang,Jiangxi Province, covering an area of 120 mu. The company is a national high-tech enterprise and a member of insulating material industry association, with advanced production equipment and precision testing equipment, professional process research and development and experienced production management team. The company has passed the ISO9001 quality management system certification, products have passed the SGS environmental protection certification, in line with the EU ROHS certification, REACH regulations and other requirements. Products are exported to all over the country and Europe, Southeast Asia, South Asia, East Asia and other regions. The company in line with the purpose of self-improvement, return to the society, uphold the integrity, pragmatic, efficient management philosophy, adhere to excellence, customer first, scientific management, continuous improvement of the quality policy. Wish to seek common development and make great achievevment with new and old customers and friends!

You may also like

Send inquiry

Send now